Horizontal Bar Run To Vertical Ground Rod Connections (BR)

Horizontal Cable Run to Horizontal Bar – T Joint ( Weld Type – BR5 )

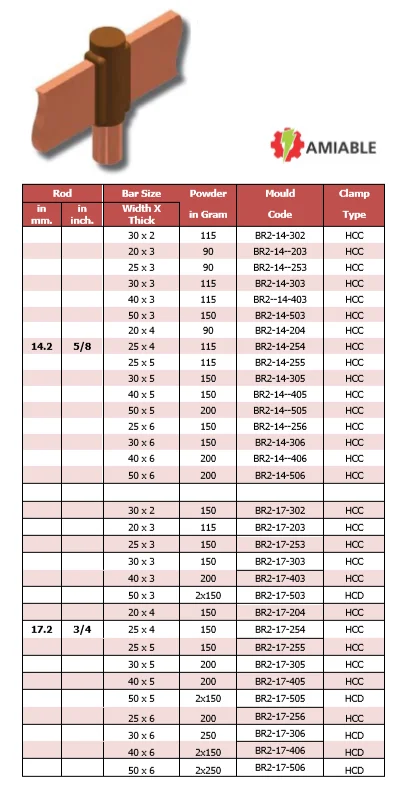

In electrical grounding systems, the reliability of connections between conductive materials is crucial for ensuring safety, efficiency, and long-term performance. The Horizontal Bar Run to Vertical Ground Rod Connections (BR), specifically the Horizontal Cable Run to Horizontal Bar – T Joint (Weld Type – BR5), is a specialized connection method that provides a secure and permanent bond between a horizontally running cable and a horizontal bar, which is then connected to a vertical ground rod. Amiable Impex, a leading manufacturer, supplier, and exporter of exothermic welding products, offers this high-quality solution to meet the demands of various industrial and commercial applications.

Understanding Horizontal Bar Run to Vertical Ground Rod Connections (BR)

Bar to ground rod connections are essential components in grounding systems, where they establish a low-resistance path to the earth to safely dissipate fault currents and protect equipment and personnel. These connections are used in various settings, including power distribution networks, telecommunications, industrial facilities, and construction projects.

High-quality bar-to-ground rod connections are designed to withstand environmental stresses, mechanical loads, and corrosion, ensuring their reliability over time. A secure connection minimizes energy loss, prevents overheating, and reduces the risk of electrical failures, making it a critical component for the safety and efficiency of any electrical installation.

The Role of Exothermic Welding in Bar to Ground Rod Connections

Exothermic welding, also known as thermite welding, is a process that creates a permanent molecular bond between conductive materials using a high-temperature chemical reaction. This reaction involves aluminum powder and metal oxide, which produce molten metal that flows into a mold and solidifies to form a robust joint. Unlike mechanical connections that may degrade or loosen over time, exothermic welds provide superior conductivity and mechanical strength, making them ideal for grounding applications.

Advantages of exothermic welding for bar-to-ground rod connections include:

- Permanent Joints: Exothermic welding forms a molecular bond, creating a permanent connection that will not loosen, corrode, or degrade over time.

- High Conductivity: The welding process ensures excellent electrical conductivity, which is crucial for maintaining system efficiency and safety in grounding applications.

- Corrosion Resistance: Exothermic welds are highly resistant to corrosion, making them suitable for use in harsh environments where exposure to moisture, chemicals, and temperature fluctuations is common.

- Maintenance-Free: Once installed, exothermic welds require no maintenance, offering a cost-effective and reliable solution for long-term applications.

Horizontal Cable Run to Horizontal Bar – T Joint (Weld Type – BR5)

The Horizontal Cable Run to Horizontal Bar – T Joint (Weld Type – BR5) is a specific configuration where a horizontally running cable is welded to a horizontal bar, forming a T joint that connects to a vertical ground rod. This type of joint is crucial for creating an efficient and continuous grounding path, ensuring effective dissipation of fault currents in grounding systems.

Key Features of BR5 Weld Type

Secure Electrical Connection: The BR5 weld type provides a strong electrical bond between the horizontal cable, the horizontal bar, and the vertical ground rod, ensuring efficient current distribution and minimizing energy loss.

Versatility in Applications: The ability to connect horizontal cables to horizontal bars and vertical ground rods makes the BR5 weld type suitable for various grounding and bonding applications in industrial and commercial environments.

Robust Mechanical Strength: The exothermic weld creates a durable mechanical bond capable of withstanding environmental challenges, including mechanical stress, temperature fluctuations, and moisture.

Easy Installation: Designed for straightforward installation with the appropriate tools and training, the BR5 weld type is a preferred choice for electrical engineers and contractors seeking reliable grounding solutions.

Benefits of Using BR5 Weld Type for Bar to Ground Rod Connections

The BR5 weld type offers several advantages for horizontal cable run-to-horizontal bar connections:

- Reliable Electrical Pathway: The BR5 weld type provides a secure and low-resistance electrical pathway, essential for effective grounding and bonding in electrical systems.

- Durability and Longevity: The robust nature of exothermic welds in the BR5 configuration ensures long-lasting durability, reducing the need for frequent maintenance and replacements.

- Versatile Application: This weld type is versatile and can be used in various applications, including power distribution grids, industrial grounding setups, and telecommunications infrastructure.

- Cost-Effectiveness: While the initial setup may require specific tools and materials, the long-term benefits of reduced maintenance and enhanced reliability make BR5 weld type connections a cost-effective choice for many projects.

Amiable Impex: Your Trusted Partner for Exothermic Welding Solutions

At Amiable Impex, we are committed to providing high-quality exothermic welding materials and equipment that meet the highest standards of performance and safety. Our BR5 weld type for horizontal bar run-to-vertical ground rod connections is engineered to deliver exceptional results across a wide range of applications. By using premium-grade materials and adhering to stringent quality control processes, we ensure that every weld meets your specifications and expectations.

Our team of experts is here to provide comprehensive support, from selecting the right products to offering installation training, ensuring your project is completed efficiently and effectively. Whether you’re working on a large infrastructure project or a smaller-scale installation, Amiable Impex has the expertise and products to meet your needs.